A modern luxury sedan in 2025 typically contains more than 100 electronic control units (ECUs) that coordinate everything from torque management to radar sensor fusion.

Collectively these controllers execute more than 100 million lines of safety-critical code and exchange messages across several in-vehicle networks.

Each ECU is a self-contained embedded system that boots in tens of milliseconds, authenticates its firmware, and publishes signals over several hundred meters of twisted-pair harness.

Bandwidth requirements have pushed powertrain and ADAS domains to adopt CAN FD at up to 8 Mbit/s, while zonal gateways and central compute nodes prepare for multi-gigabit Automotive Ethernet backbones.

Understanding this distributed architecture is fundamental for diagnostics, cyber security compliance, functional safety, and over-the-air update strategies.

This guide defines what an ECU is, outlines the main functional domains, explains typical failure modes, and shows how high-speed access to ECU data with AutoPi CAN FD Pro can support advanced diagnostics and fleet operations.

What is an ECU in a Car?

An Electronic Control Unit (ECU) is an embedded controller that manages one or more electrical or electromechanical subsystems in a vehicle. ECUs execute software that reads sensor inputs, applies calibrated control algorithms, and drives actuators on the vehicle network.

The Engine Control Unit is one example of an ECU and is responsible for air, fuel, ignition, and emissions control. Modern vehicles, however, contain many additional ECUs that handle braking, steering, body functions, restraint systems, infotainment, and connectivity.

ECUs ingest data from distributed sensors such as oxygen, temperature, pressure, position, and acceleration sensors and compute control commands in real time. This closed-loop control ensures that the powertrain operates efficiently, safety systems deploy within milliseconds, and comfort and infotainment systems behave consistently with driver inputs.

These controllers are central to fuel economy, emissions control, driveability, and occupant safety. In many platforms more than 80 ECUs are present, interconnected via multiple CAN, CAN FD, LIN, FlexRay, and Ethernet segments.

Terms such as Engine Control Module (ECM) and Electronic Control Module (ECM) are often used interchangeably with ECU. In practice they all refer to application-specific control units that supervise a subset of vehicle functions.

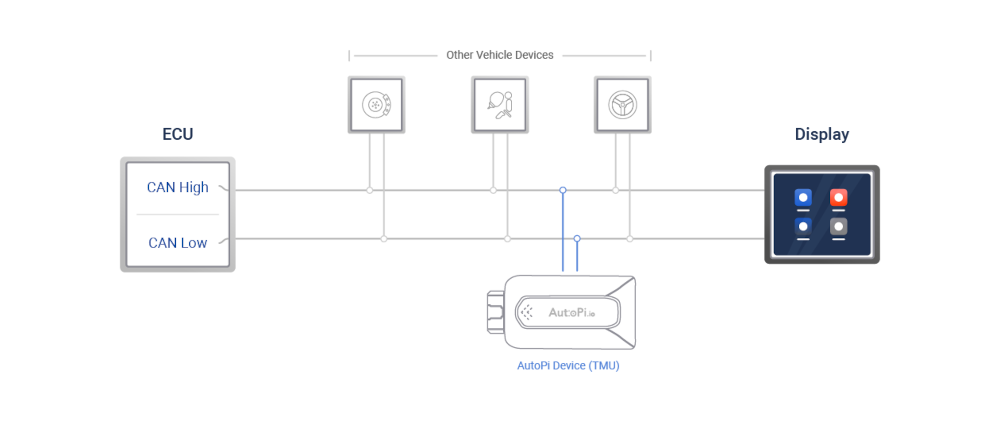

The AutoPi CAN FD Pro is a telematics and data logging device that provides high-speed access to ECU data, including CAN and CAN FD traffic, for advanced diagnostics, calibration support, and real-time monitoring in development and fleet environments.

Functional Categories of Automotive ECUs

Modern vehicles distribute computation across specialised ECUs per functional domain. Grouping controllers by domain clarifies which networks carry which signals, how safety integrity levels differ, and where over-the-air (OTA) and cyber security controls must be enforced. The table below summarises six major ECU domains, their responsibilities, typical I/O, and representative module names that commonly appear in OEM wiring diagrams.

| Domain | Primary Function | Typical Sensors / Actuators | Example ECU Names |

|---|---|---|---|

| Powertrain | Control combustion, torque delivery, and emissions | MAP, O₂, knock sensors, injectors, throttle body, turbo waste-gate, ignition coils | Engine Control Module (ECM), Transmission Control Module (TCM), Inverter Control Unit |

| Chassis / Dynamics | Manage stability, braking, traction, and steering assistance | Wheel speed, yaw rate, steering angle, brake pressure, ABS valves, EPB motor | ABS/ESC ECU, Electric Power Steering (EPS), Active Suspension Controller |

| Body and Comfort | Handle lighting, locking, HVAC, seats, and window systems | Ambient light sensors, door latches, window motors, HVAC blend motors | Body Control Module (BCM), Climate Control ECU, Door Control Module |

| ADAS and Safety | Fuse environment sensors and issue driver assistance and restraint actions | Radar, camera, LiDAR, ultrasonic sensors, accelerometers, brake booster | ADAS Domain Controller, Airbag SRSCM, Lane Keeping Assist ECU |

| Infotainment and HMI | Provide media, navigation, connectivity, and user interface | Touchscreen, GNSS receiver, audio amplifiers, steering wheel switches | Head Unit, Digital Instrument Cluster, Rear Seat Entertainment ECU |

| Telematics and Gateway | Handle external connectivity, security, and cross-domain routing | LTE or 5G modem, GNSS, Wi-Fi, Ethernet switch, secure hardware modules | Telematics Control Unit (TCU), Central Gateway, Zonal Gateway |

How an ECU Works

At a high level, an ECU implements a closed-loop control system. It acquires measurements from sensors, executes control and diagnostic software, and drives actuators according to calibrated maps and safety constraints.

Sensors distributed across the vehicle measure quantities such as engine coolant temperature, manifold pressure, air mass flow, pedal position, wheel speed, and many other parameters. These signals are digitised and forwarded to the ECU via local wiring or in-vehicle networks.

The ECU then processes the incoming data using a real-time operating system and application software. Calibrations, lookup tables, and limit values determine the exact outputs for a given operating point. The ECU finally commands actuators such as injectors, ignition coils, throttle bodies, valves, pumps, and relays, and may also transmit CAN or CAN FD messages to other controllers.

A typical example is fuel injection control. Pedal position, engine speed, air temperature, air mass, and knock feedback are combined to compute the required injection quantity and timing. The ECU then drives the injectors with precise pulse widths so that torque, emissions, and drivability targets are met while protecting hardware.

In practice, the ECU executes this loop continuously at different task rates, from sub-millisecond interrupts for low-level control to slower background tasks for diagnostics and housekeeping. Robust operation depends on accurate sensor data, correct calibrations, and stable power and ground references.

The following table summarises the main stages in a typical ECU control cycle.

| Step | Action | Description |

|---|---|---|

| 1 | Sensors collect data | Distributed sensors monitor parameters such as temperature, pressure, position, and speed. |

| 2 | Data is transmitted to the ECU | Sensor values are digitised and delivered to the ECU over local wiring or vehicle networks. |

| 3 | ECU processes data | Real-time tasks apply control algorithms and diagnostic logic using stored calibrations. |

| 4 | ECU issues commands | The ECU drives actuators or publishes commands on the vehicle network. |

| 5 | Actuators perform actions | Actuators execute the requested actions, such as adjusting fuel injection or applying brake pressure. |

| 6 | Continuous monitoring | The ECU repeats this cycle, updating outputs as conditions change. |

Signs Your Car’s ECU Might Be Failing

An ECU fault can manifest as a drivability issue, a no-start condition, or persistent diagnostic trouble codes. The symptoms below do not prove an ECU failure by themselves but indicate when ECU diagnostics should be part of the analysis.

-

Engine will not start: If the engine cranks but does not start, and fuel and ignition systems are otherwise healthy, a non-functioning ECU can prevent injection or ignition commands.

-

Check Engine light remains on: A permanently illuminated Check Engine light combined with multiple control-module-related DTCs can indicate an internal ECU fault or corrupted software.

-

Misfires and stalling: Intermittent misfires, unexpected stalling, or unstable idle can occur if the ECU does not correctly manage fuel, air, or ignition timing.

When the ECU does not correctly control start-up sequencing, the engine may receive no fuel or no spark, resulting in a crank no-start condition. In other cases the ECU may enter a protective mode and inhibit start if key sensors fail plausibility checks.

A malfunctioning ECU can also misinterpret sensor data and command incorrect air-fuel ratios or ignition timing, which leads to rough operation, increased emissions, and higher catalyst loading.

In field deployments AutoPi has observed a range of ECU-related issues, including:

-

Erratic performance: Vehicles that intermittently lose torque or enter limp mode without a clear mechanical root cause.

-

Fuel consumption degradation: Poor fuel trim control caused by faulty sensor interpretation or internal ECU errors.

-

Emissions compliance problems: Failed emissions tests due to incorrect catalyst monitoring or misreported OBD readiness flags.

Early detection and structured diagnostics reduce the risk of secondary damage and avoid extended downtime.

Use AutoPi Telematics Units to collect high-resolution ECU data for utilisation, fuel, and fault-code visibility across mixed OEM fleets.

Causes and Effects of ECU Failure

ECU failures can be electrical, environmental, or software related. Understanding the root cause is important before replacing hardware, especially in fleet environments where repeated failures may indicate a systemic issue.

Vehicle Performance Effects

When an ECU deteriorates, typical effects include stalling, misfires, loss of power, or unstable idle. Persistent operation with poor control can accelerate wear, increase fuel consumption, and trigger emission-control faults.

Over time, incorrect mixtures or ignition timing can damage pistons, valves, or aftertreatment components, leading to repair costs far exceeding the ECU itself.

Risks and Safety Issues

ECU faults in safety-related domains can introduce direct risk. Examples include sudden torque reduction in traffic, loss of power assistance for steering or braking, or incorrect deployment of restraint systems. For this reason, safety ECUs are designed according to ISO 26262 with redundancy, plausibility checks, and safe-state strategies, but they still require proper diagnostics and maintenance.

Cost of a Failing ECU

The cost impact of ECU failure includes diagnostic labour, potential towing, replacement of the unit, and any secondary component damage. Replacement parts and programming can range from a few hundred to more than one thousand dollars per vehicle, depending on brand and security requirements.

Structured monitoring and early intervention significantly reduce the probability of major ECU-related repair events and associated downtime.

Typical Causes of ECU Failure

Common root causes include:

-

Water ingress: Moisture or condensation inside the housing can corrode PCB traces and connector pins.

-

Electrical overstress: Voltage spikes, incorrect jump-start procedures, shorts, or faulty wiring can damage power stages and logic.

-

Thermal stress: Continuous exposure to elevated temperatures near the engine or exhaust can accelerate component ageing and lead to intermittent faults.

-

Ageing and vibration: Solder joint fatigue, connector wear, and long-term thermal cycling can cause intermittent behaviour.

How to Reduce ECU Failure Risk

Preventive measures focus on protecting the ECU environment and detecting anomalies early:

-

Electrical inspections: Verify grounds, battery condition, and charging system performance to avoid voltage excursions.

-

Moisture protection: Ensure housings, grommets, and connectors remain sealed, especially in harsh-duty environments.

-

Thermal management: Keep cooling systems in good condition and avoid blocking airflow around ECUs in the engine bay.

-

Professional diagnostics: Use proper tooling to distinguish between ECU faults, wiring issues, and sensor failures before replacing components.

Continuous monitoring of ECU data can extend this preventive approach by highlighting abnormal patterns before they escalate into failures.

Monitoring ECU Health with AutoPi CAN FD Pro

With AutoPi CAN FD Pro, engineers and fleet operators can observe ECU behaviour in real time over CAN and CAN FD. The device captures diagnostic trouble codes, live parameters, and raw frames, and forwards them to AutoPi Cloud for analysis, alerting, and reporting.

This enables early detection of abnormal temperatures, intermittent bus errors, repeated DTC patterns, and other precursors to ECU failure. Automated alerts and dashboards reduce manual inspection load and support data-driven maintenance planning.

Troubleshooting and Replacing an ECU

When ECU-related issues are suspected, a structured diagnostic workflow is essential. The steps below outline a typical process from fault code retrieval to possible replacement.

Understanding ECU Error Codes

When the Check Engine or equivalent malfunction indicator lamp is active, the ECU stores diagnostic trouble codes (DTCs) that describe the detected fault. Examples include:

-

P0171: System too lean (Bank 1). Indicates excess air or insufficient fuel.

-

P0300: Random or multiple cylinder misfire detected.

-

P0420: Catalyst system efficiency below threshold. Often associated with aftertreatment degradation or sensor faults.

For more background on reading these codes, see the guide on how to read OBD2 codes.

Reading and Interpreting Error Codes

An OBD-II or UDS-capable diagnostic tool is used to access ECU fault memory:

-

Connect an OBD-II or CAN interface: Attach the tool to the vehicle’s diagnostic connector.

-

Establish communication: Switch ignition on and select the appropriate protocol and ECU.

-

Retrieve DTCs and freeze-frame data: Read stored and pending codes along with associated snapshots.

-

Correlate codes with live data: Compare DTCs with live parameters to separate wiring, sensor, and ECU faults.

For a step-by-step introduction to diagnostic tooling, see the overview on using an OBD2 scanner.

Escalation to a specialist workshop is recommended if codes point to core powertrain control faults, immobiliser issues, or control module internal errors that require programming access and security credentials.

Replacing an ECU

If diagnostic results confirm that an ECU is defective and repair is not feasible, the replacement procedure typically includes:

-

Confirm diagnosis: Rule out wiring, power, ground, and sensor faults before condemning the ECU.

-

Isolate power: Disconnect the battery according to OEM procedure to prevent damage.

-

Remove the ECU: Access the module in the engine bay, cabin, or luggage compartment and disconnect connectors and fasteners.

-

Install the replacement unit: Fit the new ECU, reconnect harnesses, and secure mechanical fixings.

-

Program and code: Load the correct software, perform immobiliser pairing if required, and adapt calibrations where applicable.

For advanced troubleshooting and live data during and after replacement, AutoPi CAN FD Pro provides high-speed access to ECU traffic and diagnostic sessions.

Cost of ECU Replacement

Replacement cost varies by OEM, vehicle segment, and security scheme but often falls in the range of 300 to more than 1,000 USD including programming. Incorrect diagnosis that leads to unnecessary ECU replacement can significantly increase cost, which underlines the importance of methodical testing.

Disclaimer

The information in this guide is intended as a general overview. ECU diagnostics and replacement involve safety-critical systems and should only be performed by qualified personnel following OEM procedures and applicable regulations.

Finding a Qualified Workshop

Selecting an appropriate workshop is important for any ECU-related work:

-

Verify certifications: Prefer workshops with OEM approvals or relevant independent certifications.

-

Review capabilities: Confirm that the workshop has access to suitable diagnostic tools and programming infrastructure.

-

Compare quotations: Obtain multiple estimates for complex ECU work and verify what is included in programming and coding fees.

Conclusion

The ECU architecture of a modern vehicle forms the core of its performance, safety, and connectivity. ECUs manage powertrain behaviour, coordinate chassis dynamics, supervise restraint systems, and expose data that supports diagnostics and fleet analytics.

A clear understanding of ECU roles, control cycles, and failure modes helps engineers and fleet operators diagnose issues faster, reduce downtime, and plan more effective maintenance strategies. Combined with high-speed data access through AutoPi CAN FD Pro and AutoPi Cloud, ECU data becomes a practical tool for optimizing utilisation, energy consumption, and uptime across mixed fleets.

Additional Reading

For further technical context, see:

For more detailed information or to discuss ECU data acquisition in your project or fleet, contact AutoPi.