In both commercial trucking and public transportation, the Driver Vehicle Inspection Report (DVIR) is not just a form; it is a frontline safety control that prevents small issues from becoming costly incidents. A disciplined DVIR routine creates a clear record that vehicles were inspected, defects were handled correctly, and repairs were verified before the next dispatch. When drivers follow a consistent process and supervisors review results regularly, fleets see fewer out-of-service events, faster roadside inspections, and a healthier CSA profile across regions and routes.

This guide brings the DVIR essentials into one place: what the report is, how pre-trip and post-trip inspections fit together, which components must be checked, how to document and route defects, and how long records should be retained. You will also find practical guidance for moving from paper forms to electronic DVIR (eDVIR) so you can attach photos and locations, streamline maintenance handoffs, and build a searchable audit trail that stands up during inspections and carrier reviews.

What is DVIR?

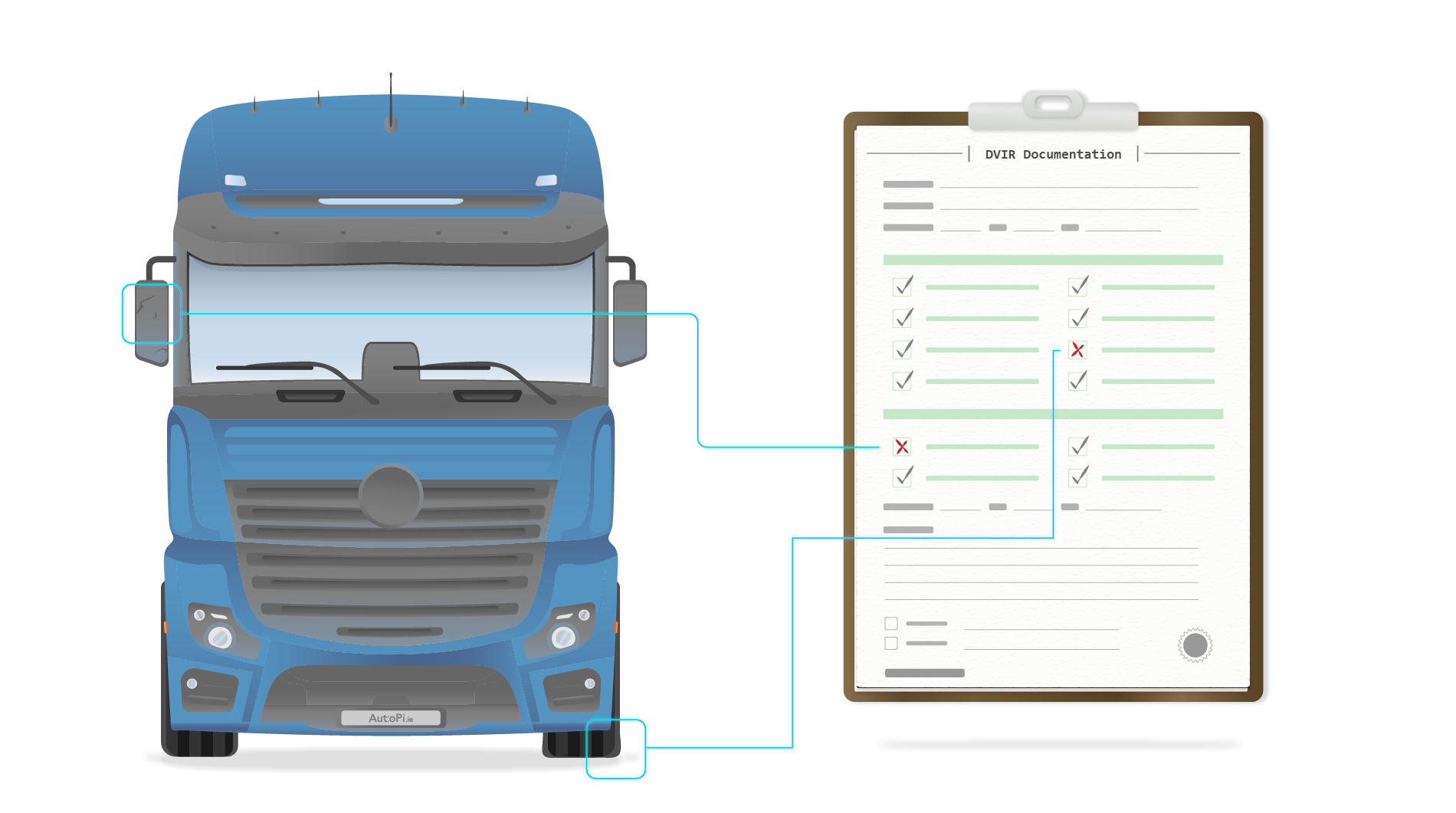

A Driver Vehicle Inspection Report is the driver’s documented verification that a commercial motor vehicle is in safe operating condition. Under FMCSA rules, drivers perform daily inspections and record any defects that could affect safety. If a safety-critical issue is found, the vehicle must be removed from service until repairs are completed, the correction is certified by maintenance, and the next driver acknowledges the fix. Treating DVIR as a closed-loop safety practice, rather than a paperwork task, is what keeps vehicles roadworthy and liability low.

Fleet vehicles must be checked before and after use with attention to brakes, steering, tires, lighting, coupling, suspension, and emergency equipment that ensure safe operation. Strong programs capture odometer, time, and location automatically, and require clear descriptions for any defect so maintenance can prioritize and respond without delay. Supervisors should spot trends, coach on recurring issues, and verify that repairs are documented on the original DVIR.

A DVIR works best when it is specific and fast. Drivers should submit reports as soon as the inspection is complete, attach photos when they help describe a condition, and route the defect to the carrier or shop automatically. For serious issues, policy should be unambiguous: ground the vehicle, record the reason, and release it only after repair certification and next-driver acknowledgment are documented in the same record.

The Crucial Role of DVIRs

Federal regulations require inspection reports to protect drivers, the public, and the carrier. A consistent DVIR process identifies defects early, prevents unsafe vehicles from entering service, and builds a transparent maintenance history for each unit and trailer. Because the record shows who inspected, what was found, how it was fixed, and who verified the repair, enforcement can confirm compliance quickly. The operational payoff is fewer violations, less downtime at the scale house, and greater confidence in the condition of your fleet.

How does a typical DVIR inspection look like?

A solid routine starts the same way every day: the driver reviews the previous DVIR for the assigned unit and trailer, confirms any listed defects were corrected or do not require repair, and then performs the pre-trip inspection using a checklist. After the trip, the driver completes the post-trip inspection, recording any new defects with enough detail to act on. If a defect affects safe operation, the driver alerts the carrier immediately so maintenance can create a work order and certify the fix before the next dispatch.

| Step in DVIR process | Vehicle component | Action required | Responsible party |

|---|---|---|---|

| Pre-trip inspection | Brakes | Check wear, adjustment, leaks; verify warning systems | Driver |

| Pre-trip inspection | Steering | Verify responsiveness; check play, alignment, and fluid leaks | Driver |

| Pre-trip inspection | Lighting | Confirm headlamps, brake, turn, and marker lights operate | Driver |

| Post-trip inspection | Brakes | Recheck for heat cracks, leaks, or changed pedal feel | Driver |

| Post-trip inspection | Steering | Confirm no new noise, pull, or vibration | Driver |

| Post-trip inspection | Lighting | Ensure all lights remain operational | Driver |

| Defect identification | Any critical component | Record defect with notes and photos; include odometer and location | Driver |

| Defect reporting | N/A | Notify carrier or intermodal equipment provider; open work order | Driver |

| Repair action | Defective component | Repair and certify correction or “not necessary” for safe operation | Carrier/Maintenance |

| Compliance verification | Entire vehicle | Next driver reviews the DVIR and acknowledges repair | Driver & Carrier |

Follow this flow on every day the vehicle is used. It reduces roadside delays, speeds maintenance decisions, and ensures the repair certification and next-driver acknowledgment live with the original DVIR for easy retrieval during audits.

What are DVIRs Requirements?

DVIR is a federally mandated process designed to confirm that commercial vehicles are safe and operational before and after use. A strong policy requires reviewing the previous DVIR, documenting defects with enough detail to act, and verifying corrections before the next dispatch. When this discipline is applied consistently across drivers and terminals, fleets lower violation rates and keep equipment where it belongs: on the road serving customers.

Key Requirements

Daily inspections: Perform and record pre-trip and post-trip checks every day a vehicle is used. Drivers should also review the previous DVIR for the unit and trailer.

Items to inspect: Brakes, steering, tires, lighting, coupling devices, suspension, and emergency equipment. Adjust lists by vehicle class and route profile but keep safety-critical systems mandatory.

Record keeping: Complete and sign a DVIR with clear notes and, when useful, photos and geo-location. Make sure timestamps, odometer, and unit IDs are captured consistently.

Defect reporting: Notify the carrier or agent immediately for issues affecting safe operation. Open a work order, track the repair, and certify the correction on the same record.

Retention: Carriers retain DVIRs for at least three months after the inspection date. Many fleets keep eDVIR longer to support trend analysis, warranty claims, and quick document retrieval during audits.

Are there penalties for non-compliance?

Missing, incomplete, or inaccurate DVIRs can lead to fines, vehicles placed out of service, and negative impact on your CSA score. The best defense is a clean eDVIR trail tied to each unit and trailer: complete inspections, fast defect routing, repair certifications, and next-driver acknowledgments that are simple to produce when enforcement asks.

Electronic Options

DVIRs can be recorded on paper or as eDVIR. Electronic workflows reduce handwriting errors, attach photos and location automatically, and preserve signatures and timestamps. eDVIR also integrates with ELD and maintenance systems so the inspection, the defect, and the repair live in one place and can be exported in standardized formats for audits.

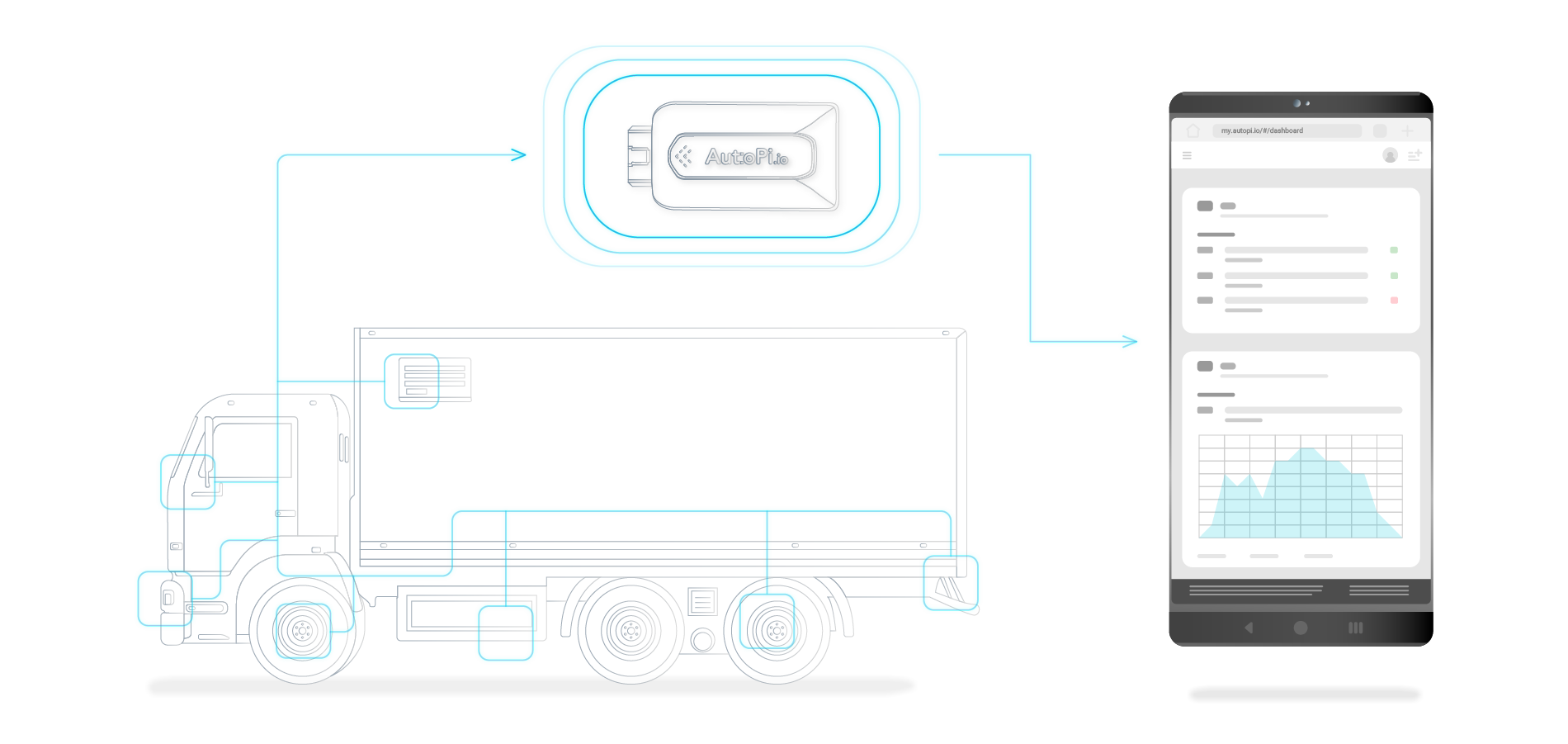

Data Loggers: A Partner in Compliance and Safety

Using automotive data loggers in fleet management strengthens DVIR by making key details automatic and reliable. A compact telematics dongle on the OBD2 port provides real-time monitoring of odometer and health signals, while location data ties defects to a place and time. In AutoPi Cloud, drivers and shops can view the same record, attach repair notes, and close the loop with verified sign-offs.

How Do I Complete a Driver Vehicle Inspection Report (DVIR)?

Start with a standardized checklist and walk the vehicle the same way every time. Inspect brakes, steering, tires and wheels, lighting, coupling, suspension, and emergency equipment. Record findings on the DVIR with any photos needed to clarify the condition, then sign and date the report. If the defect affects safe operation, inform the carrier, ground the vehicle as required, create the work order, and capture the maintenance certification and next-driver acknowledgment before returning to service.

When is Completing and Signing a DVIR Required?

Complete and sign a DVIR during the pre-trip review and again after the trip (post-trip) on every day the vehicle is used. Drivers should also review the previous DVIR and confirm that noted defects were corrected or do not require repair before operating the vehicle. Consistency keeps vehicles safe and makes enforcement interactions faster and more predictable.

What is the Purpose of Reviewing the DVIR Book?

Reviewing DVIR history confirms the vehicle’s condition over time and helps carriers track maintenance and spot recurring failures before they become breakdowns. It builds accountability, supports warranty claims, and provides clear evidence that the fleet follows a documented safety process that meets regulatory expectations.

How Long Should DVIRs be Retained on File?

According to federal rules, motor carriers must retain DVIRs for at least three months after the inspection date. Many fleets keep electronic records longer to support trend analysis and rapid document retrieval during audits. Keeping repair certifications and next-driver acknowledgments with the original DVIR ensures the record remains complete and defensible.

Do not risk penalties or roadside delays. Standardize DVIR across your operation, move to eDVIR where possible, and link inspections to work orders so every report tells a complete story from defect to verified repair.