Predictive maintenance is the application of data-driven, proactive maintenance approaches to examine the state of equipment and anticipate when repair should be conducted.

What is Predictive Maintenance?

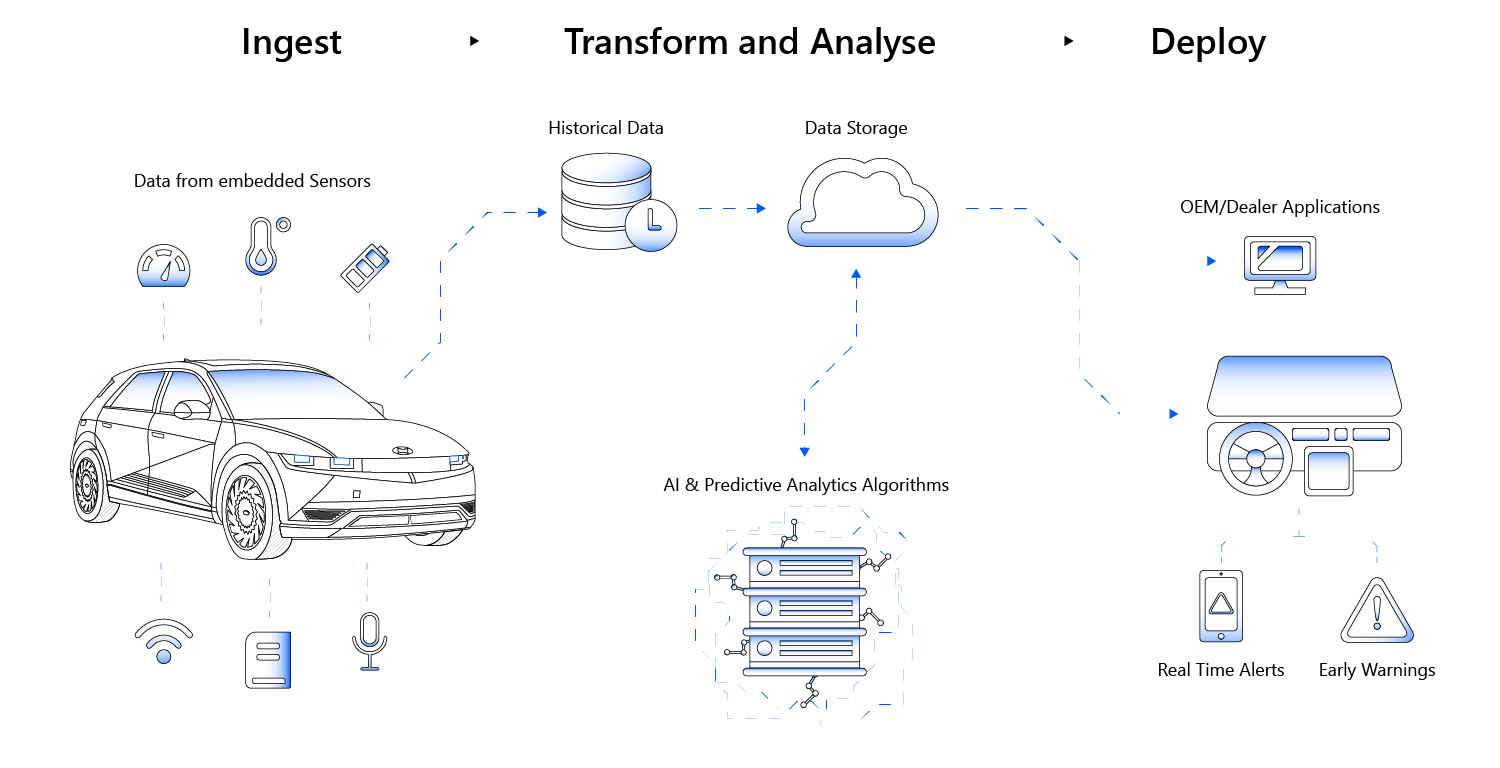

Predictive maintenance is a condition-based maintenance strategy that uses sensor devices to monitor the state of assets. These sensor devices provide real-time data that is used to forecast when an asset will require maintenance and to prevent equipment failure.

Predictive maintenance architectures often include data gathering and storage, data translation, condition monitoring, asset health evaluation, prognostics, a decision support system, and a human interface layer. The architecture can be used in various industries such as: Heavy Equipment Management, Supply Chain Logistics, and Utility Management.

Predictive maintenance is critical in sectors where machine components must be available at all times. It is distinguished from reactive and preventative maintenance:

-

Reactive maintenance entails running equipment until it fails, then repairing or replacing it.

-

Preventive maintenance includes replacing parts and scheduling equipment repairs on a time- or machine-run basis.

-

Predictive maintenance uses sophisticated sensors to monitor machine parts in operation and machine learning to detect when data deviates from expected values.

Preventive Maintenance vs. Predictive Maintenance

While preventive maintenance is established by using an asset's typical life cycle, predictive maintenance is identified based on preset and predetermined circumstances of specific pieces of equipment using various technologies. Predictive maintenance likewise necessitates more expenditures in personnel, training, and equipment than preventive maintenance, but the long-term time and cost benefits will be larger.

In short, the distinction between preventive and predictive maintenance is found in the data being evaluated.

While a predictive maintenance professional monitors and analyzes data from the real, current state of the equipment in operation, preventive maintenance professional relies on previous data, averages, and life expectancy to estimate when maintenance operations will be necessary.

How to implement Predictive Maintenance

The major benefit of predictive maintenance is the ability to plan work based on the existing state of the asset. However, determining the precise state of complex assets is anything but simple. Creating a sustainable system requires laying the framework for predictive maintenance. It is critical to begin small and gradually build up as the company adjusts to this new structure.

In general, there are seven phases to creating a predictive maintenance program:

-

Plan out the budget.

-

Determine important assets.

-

Create a database.

-

Examine failure modes.

-

Incorporate condition-based monitoring (CBM).

-

Create prediction models.

-

Deploy the pilot equipment.

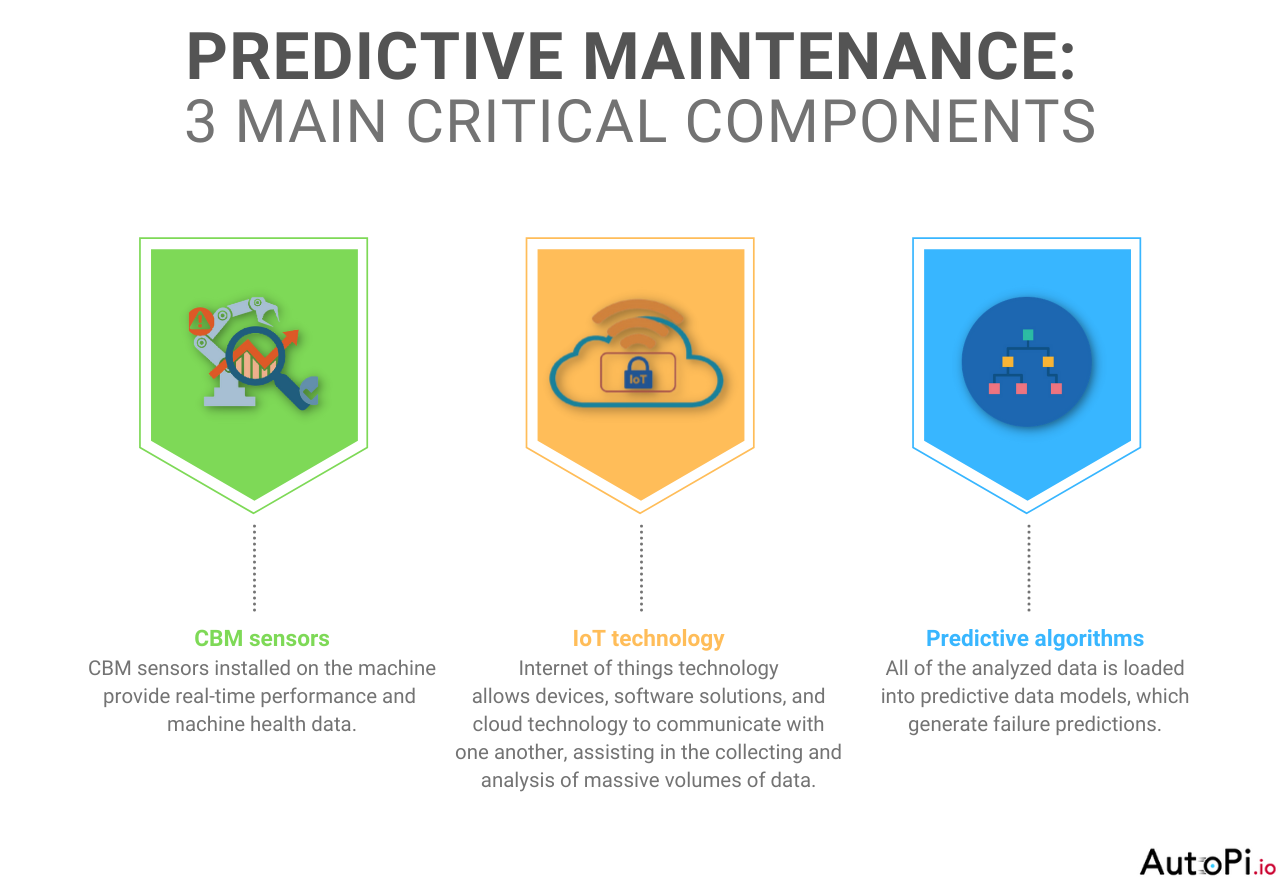

However, adopting predictive maintenance will be futile without these three primary important components that allow predictive maintenance to track asset status and advise workers about probable equipment failures:

-

CBM sensors installed on the machine provide real-time performance and machine health data.

CBM sensors and equipment are available in a range of configurations. Electrical currents, vibrations, temperature, pressure, oil, noise, corrosion levels, and so on are some examples.

Another advantage of employing CBM sensors is that you can get an accurate depiction of what is going on inside the asset without causing any disruptions in production. To put it another way, you don't have to stop the asset and disassemble it to undertake physical inspections.

-

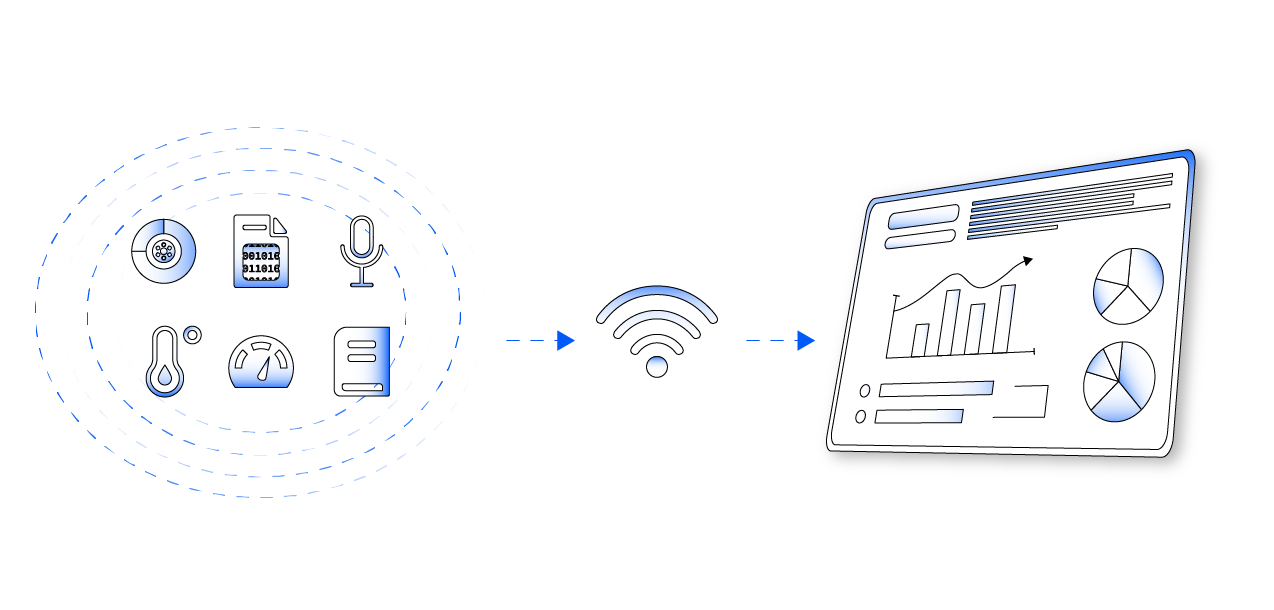

Internet of things (IoT) technology allows devices, software solutions, and cloud technology to communicate with one another, assisting in the collection and analysis of massive volumes of data.

It is one thing to collect data; it is quite another to evaluate and apply the data for its intended purpose. Sensors can gather and distribute data by utilizing IoT technologies.

Predictive maintenance mainly depends on these sensors to connect assets to a central system that saves data. These central hubs are powered by WLAN or LAN connectivity, as well as cloud technologies. Depending on how the system is configured, the assets can then communicate, collaborate, analyze data, offer corrective measures, or take direct action.

-

All of the analyzed data is loaded into predictive data models, which generate failure predictions.

Building predictive algorithms is the most crucial and challenging aspect of predictive maintenance. In essence, you must create a model that takes into account a wide range of factors and how they interact and effect one another, with the ultimate objective of predicting machine failure. The more variables you have at your disposal, the more accurate your models will be. As a result, developing predictive models is an iterative process.

The placed sensors will create an increasing amount of data over time, which may be utilized to enhance the basic models and achieve near-perfect failure predictions.

Here's how the algorithms operate, without getting too technical:

They operate according to a set of established rules that match the asset's present behavior to its predicted performance. Deviations indicate a slow deterioration that will lead to asset collapse. The algorithms attempt to anticipate failure spots based on deviations, present operating circumstances, prior failure data, and all of the other factors integrated into the data model.

As a consequence, an automated system is created that:

-

Monitors operational conditions using installed sensors.

-

Recognizes and anticipates patterns caused by data abnormalities.

-

When there is a departure from the set thresholds, an alert is generated.

Why should you use the AutoPi TMU device?

-

The automotive interface has been improved.

-

The operating system runs LINUX OS.

-

Open source software

-

Computer processing power.

The AutoPi TMU device is a Wi-Fi CAN bus data recorder that is excellent for CAN-based asset predictive maintenance.

The device includes two May FD ports and can be upgraded with additional CAN interfaces. Diagnostics over IP (DoIP) support for Raspberry Pi 3B+ and above.

AutoPi Core is built on a complete LINUX OS (Raspberry Pi OS), with limitless expansion and integration options. OS that has been tried and tested and has a high endurance.

The gadget is powered by open source software, allowing users to create custom programming on top of it. Our GitHub repository contains all of the drivers and implementations in AutoPi Core.

A quad-core CPU offers amazing speed and functionality. Broadcom BCM2837B0 quad-core 64-bit CPU @ 1.4 GHz. It has 512MB of RAM and an integrated GPU. Raspberry Pi 4 allows for even faster performance.

Learn more about the AutoPi TMU device.

Predictive maintenance has an impact on the bottom line

Predictive maintenance insights are a useful tool in enhancing an operation's overall maintenance and dependability. Furthermore, it aims to establish the ideal time to do maintenance on an asset so that the frequency of maintenance is as low as feasible, and the dependability is as high as possible without incurring needless expenditures.

When predictive maintenance is used properly as a maintenance approach, machines are only serviced when they are needed. That is, shortly before failure is expected to occur, resulting in a number of cost savings:

-

The equipment is being maintained in order to reduce the amount of time spent on it.

-

Reducing the number of production hours wasted due to maintenance.

-

Keeping spare parts and supplies to a minimum.

Predictive maintenance systems have been demonstrated to result in a 10x gain in ROI, a 25%-30% reduction in maintenance expenditures, a 70%-75% reduction in failures, and a 35-45% reduction in downtime. As a result, the bottom line will benefit.

Other advantages may include:

-

Reducing the amount of unexpected breakdowns.

-

Improve asset dependability and maximize asset uptime.

-

Increase safety.

-

Reduce maintenance expenses by reducing equipment, inventory, and personnel.

Predictive maintenance is not appropriate for many organizations, particularly those that have yet to undertake scheduled maintenance operations. However, for larger firms that have outgrown typical preventive maintenances’ and have extra funding, predictive maintenance may give a ROI that transforms the maintenance department into a source of cost savings and increased revenues.

Discover more about the AutoPi IoT platform.